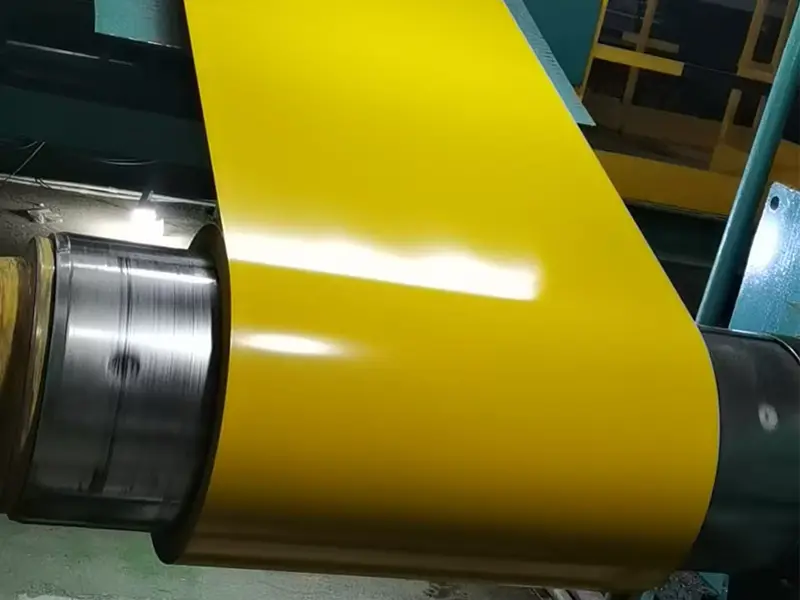

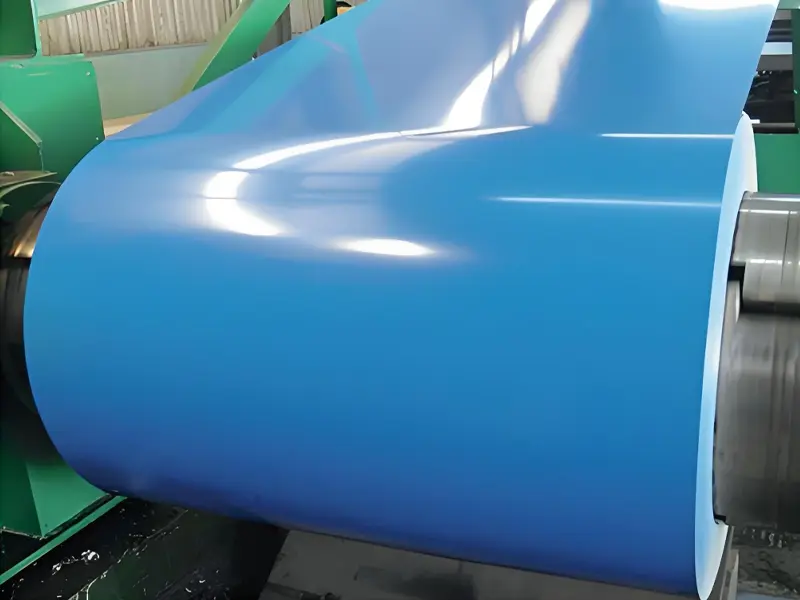

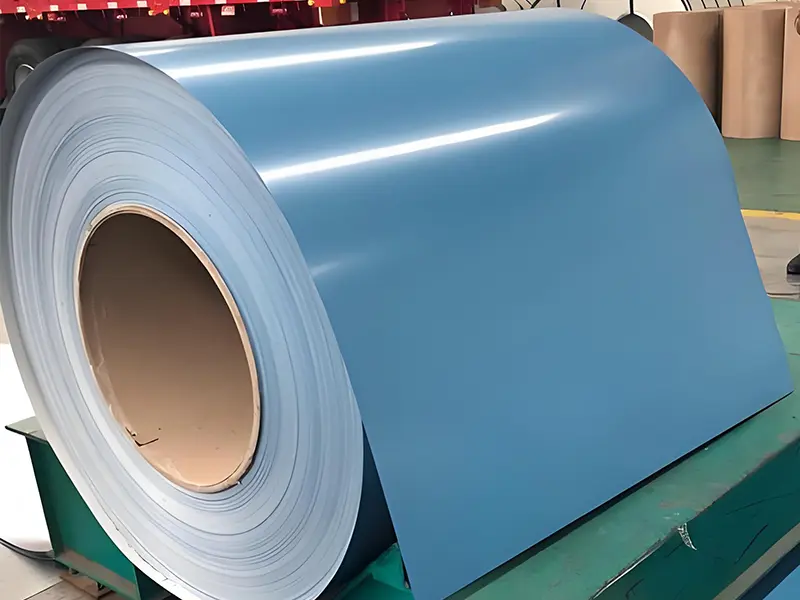

PVDF fluorocarbon coated coil

Category:

Color-coated Sheets

Keywords:

PVDF fluorocarbon coated coil

E-mai:mike@chuangcaigroup.com

WhatsApp:+86-18654318088

- Details

-

PVDF fluorocarbon coatings are the top-of-the-line among existing architectural coatings. As a recognized organic coating with optimal protective properties, it protects metal building panels from damage and maintains its vibrant color for decades. To date, PVDF fluorocarbon coatings have been used in global construction for over 30 years. Today, these buildings still look brand new. PVDF stands for polyvinylidene fluoride. Fluorine atoms have the highest electronegativity and can form very stable carbon-fluorine bonds; its molecules are unique. Therefore, PVDF possesses superior stability, unique resistance to UV photolysis, and exceptional insulation and mechanical properties.

I. Definition of Fluorocarbon Coated Panels:

Fluorocarbon coated panels are colored, baked enamel metal panels created by applying a PVDF fluorocarbon polyester coating to metal panels and baking them at high temperatures.

II. Characteristics of Fluorocarbon Coated Panels:

1. Possesses superior stability, maintaining various performance stabilities even in highly acidic, alkaline, and polluted environments.

2. Excellent durability; fluorocarbon coated panels can maintain good color and gloss for 20 years outdoors.

3. Superior processing performance; coated color steel sheets have high toughness and impact resistance and can be processed after embossing.

III. Uses of Fluorocarbon Color-Coated Panels:

IV. Main Indicators of Fluorocarbon Coatings

Fluorocarbon resin content in the coating: ≥70%.

Specific gravity: 1.20±0.1kg/kg

Coating weight: 330㎡/kg (based on 1um dry film)

Solid content 42±2% (weight), 38±2% (volume)

Packaging viscosity: 100~120s

PMT: 249~254℃ (metal peak temperature, referring to the peak temperature of the steel strip surface)

Salt spray test >1000h

MEK: >150 times (MEK wiping)

T-bend 0~1T

Reverse impact >9J

Gloss (60°): 15~40%

Hardness >F

The PVDF coating on the steel sheet is made of polyvinylidene fluoride, a highly durable and weather-resistant material. This coating is highly resistant to ultraviolet radiation, moisture, and other environmental factors, making it suitable for both indoor and outdoor applications.

PVDF fluorocarbon color-coated steel sheets are known for their excellent color retention and vibrant appearance. Even under harsh weather conditions, the PVDF coating ensures that the color remains vibrant and does not fade easily, providing lasting aesthetics and protection.

In addition to aesthetics, PVDF fluorocarbon color-coated steel sheets also have excellent durability. It has strong scratch resistance, wear resistance, and corrosion resistance, ensuring long-term performance and minimizing maintenance needs.

Product Specifications

Coil Thickness 0.085-1.0mm Coating Structure 2/2 Double layer front/Double layer back Coil Width 10-1250mm 2/1 Double coating front and back Coil Inner Diameter Ф508mm/Ф610mm 1/1 Double coating front/Double coating back Coil Outer Diameter 800-1500mm Color Colors can be customized according to customer requirements. Coil Weight 2-10T Thickness Front 15-30 um, Back 5-25 um Color-coated steel sheet color chart

Yes, we are a manufacturer specializing in the production and sale of high quality metal products. Over the years, we have been committed to providing customers with high-quality carbon steel plate/coil, stainless steel plate/coil, PPGI/PPGL, square pile end plate, all kinds of bolts and other metal products.

OEM with competitive price,Full of inventory with large warehouse, Complete sizes,grade and MOQ,24 hours online service, feedback within one hour.More important, we have raw material advantages,and the ppgi coil can be supplied with certification and test.

First our clients can visit factory to see the raw material, production lines, warehouse, transportation and inspection workshop.And you can ask for free sample, we can also process goods as your special requirements. Please do not hesitate to contact us.

If we have the products on stock, delivery time within 15 days. Otherwise, it will take about 25 days for production and delivery.

Please send us the exact details of products inquiry, such as material grade, size(thickness, width, quantity), etc. Then we will quote the best price as you accordingly.

Related Products

Galvanized Sheets

-

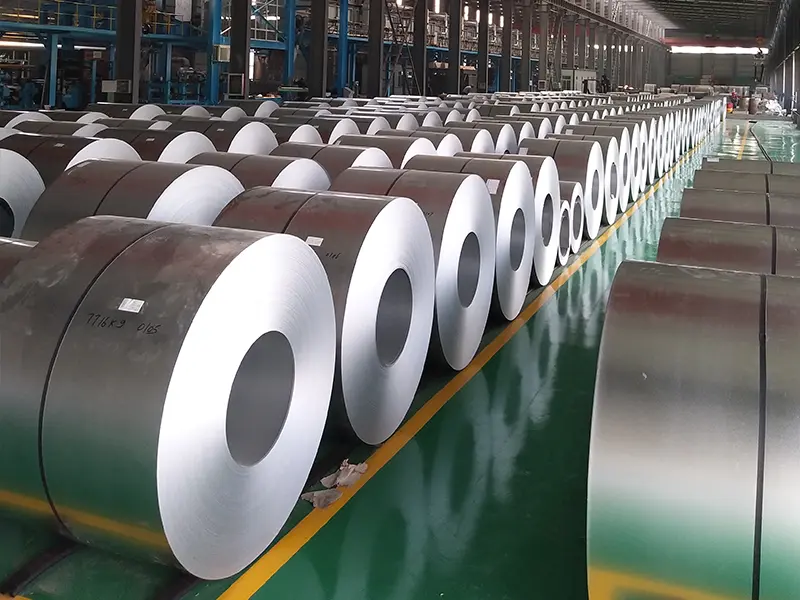

Uncoated galvanized steel coil

Widely used in building materials and decoration (composite panels, polished tiles, rolling doors), daily necessities (washing machines, refrigerators, ovens), packaging containers, and other fields.

-

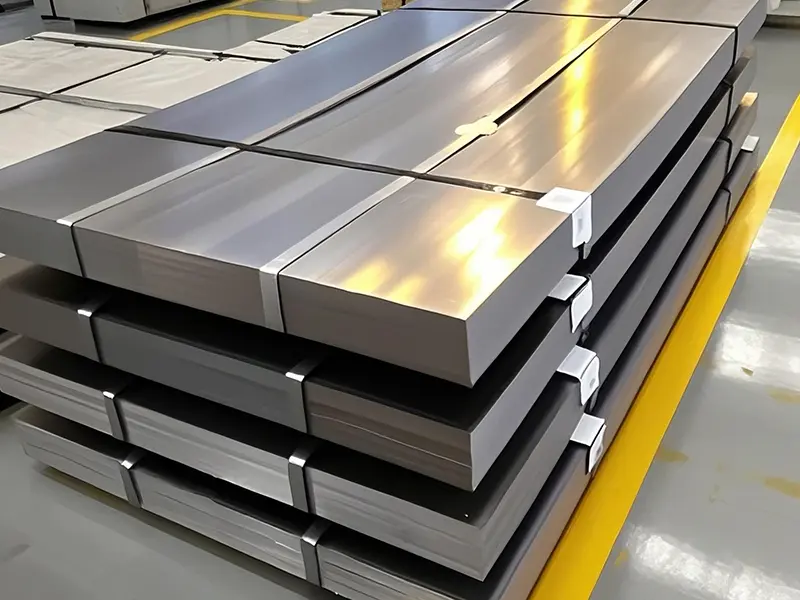

Galvanized sheet

Widely used in building materials and decoration (composite panels, polished tiles, rolling doors), daily necessities (washing machines, refrigerators, ovens), packaging containers, and other fields.

-

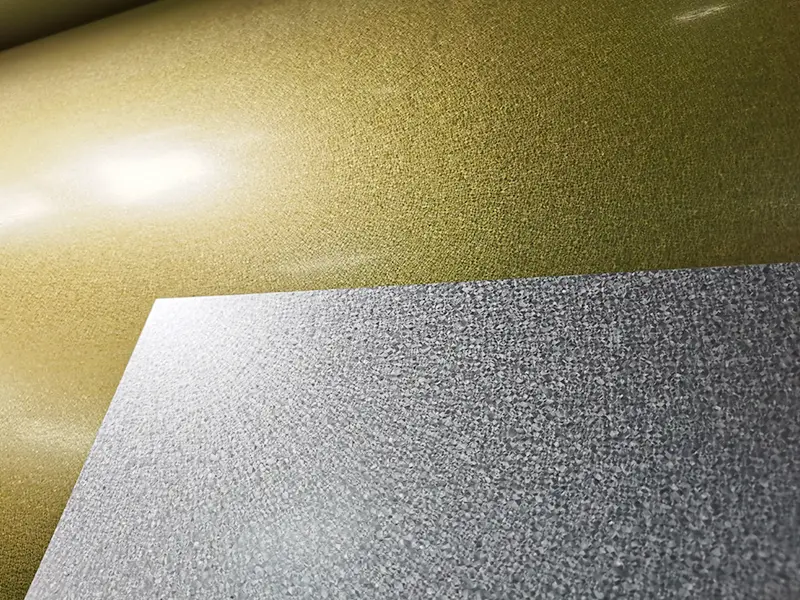

Large zinc flower galvanized coil

Hot-dip galvanized steel sheets have a smooth and aesthetically pleasing surface, and are widely used in industries such as pre-coated base plates, construction, home appliances, automobiles, and container manufacturing.

-

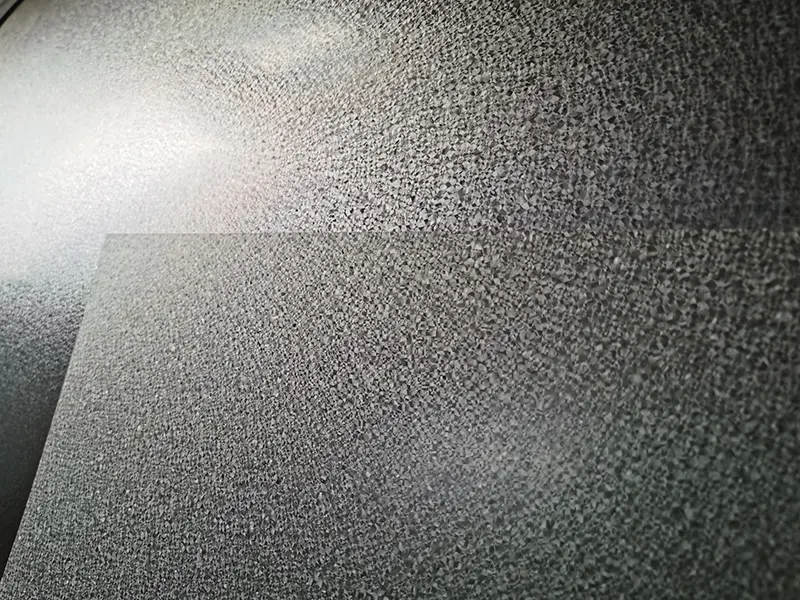

Galvanized sheet

Hot-dip galvanized steel sheets have a smooth and aesthetically pleasing surface, and are widely used in industries such as pre-coated base plates, construction, home appliances, automobiles, and container manufacturing.

-

Hot-dip galvanized steel coil

Hot-dip galvanized steel sheets have a smooth and aesthetically pleasing surface, and are widely used in industries such as pre-coated base plates, construction, home appliances, automobiles, and container manufacturing.

-

Galvanized sheet

Hot-dip galvanized steel sheets have a smooth and aesthetically pleasing surface, and are widely used in industries such as pre-coated base plates, construction, home appliances, automobiles, and container manufacturing.

-

Galvanized sheet

Hot-dip galvanized steel sheets have a smooth and aesthetically pleasing surface, and are widely used in industries such as pre-coated base plates, construction, home appliances, automobiles, and container manufacturing.

-

Galvanized sheet

Hot-dip galvanized steel sheets have a smooth and aesthetically pleasing surface, and are widely used in industries such as pre-coated base plates, construction, home appliances, automobiles, and container manufacturing.

Galvalume

-

55%-AL aluminum-zinc coated steel sheet (GL)

55%-AL aluminum-coated steel coils are widely used in various fields, including roofing, wall cladding, structural components, and automotive manufacturing. Their excellent corrosion resistance and durability make them suitable for both indoor and outdoor applications, even in highly corrosive environments.

-

Galvanized aluminum zinc coated steel sheet (GL)

Galvanized aluminum zinc steel coils also have excellent thermal reflectivity, reducing heat transfer into buildings or structures in hot climates, thereby improving energy efficiency. This feature helps reduce energy consumption and improve comfort.

-

Galvanized aluminum zinc coated steel sheet (GL)

Galvanized aluminum zinc steel coils also have excellent thermal reflectivity, reducing heat transfer into buildings or structures in hot climates, thereby improving energy efficiency. This feature helps reduce energy consumption and improve comfort.

-

Galvanized aluminum zinc coated steel sheet (GL)

55%-AL aluminum-coated steel coils are available in various thicknesses and widths to meet different project requirements. Depending on the specific design needs, the coils can be further processed into sheets, profiles, or other custom shapes.

-

55%-AL aluminum-zinc coated steel sheet (GL)

55%-AL aluminum-coated steel coil, also known as GL (Galvalume), is a continuously hot-dip metal-coated steel coil composed of 55% aluminum and 45% zinc. Compared with traditional galvanized steel, the combination of aluminum and zinc enhances corrosion resistance and extends service life.

-

55%-AL aluminum-zinc coated steel sheet (GL)

55%-AL aluminum-coated steel coil, also known as GL (Galvalume), is a continuously hot-dip metal-coated steel coil composed of 55% aluminum and 45% zinc. Compared with traditional galvanized steel, the combination of aluminum and zinc enhances corrosion resistance and extends service life.

-

55%-AL aluminum-zinc coated steel sheet (GL)

55%-AL aluminum-coated steel coil, also known as GL (Galvalume), is a continuously hot-dip metal-coated steel coil composed of 55% aluminum and 45% zinc. Compared with traditional galvanized steel, the combination of aluminum and zinc enhances corrosion resistance and extends service life.

Color-coated Sheets

-

Color-coated steel coil (PPGI)

Its coating quality is far more uniform, stable, and ideal than that of single-piece spraying or brushing on formed metal surfaces. Color-coated steel sheets have good decorative properties, formability, and corrosion resistance. The coating has strong adhesion and can maintain its novel color for a long time.

-

Color-coated aluminum zinc steel coil PPGL

Because color-coated steel plates can achieve the goals of replacing wood with steel, efficient construction, energy saving, and pollution prevention, they offer significant economic benefits and have become an ideal material for manufacturing building materials today.

-

Color-coated embossed metal sheet

The coating quality is far more uniform, stable, and ideal than single-piece spraying or brushing on the surface of the formed metal.

-

PVDF fluorocarbon coated coil

The PVDF coating on the steel sheet is made of polyvinylidene fluoride, a highly durable and weather-resistant material. This coating is highly resistant to ultraviolet light, moisture, and other environmental factors, making it suitable for both indoor and outdoor applications.

-

Stainless steel color-coated plate

Mainstream color-coated products, moderately priced and easily accepted by your customers.

-

PVDF fluorocarbon coated coil

PVDF fluorocarbon coated steel plate is renowned for its excellent color retention and vibrant appearance. Even under harsh weather conditions, the PVDF coating ensures that the color remains vivid and resistant to fading, providing lasting aesthetics and protection.

-

Aluminum magnesium manganese color-coated steel plate

This board material possesses high strength and rigidity, while also exhibiting a degree of flexibility. It can withstand heavy loads, is resistant to deformation, and can be used as a load-bearing component in building structures.

-

Aluminum magnesium manganese color-coated steel plate

Aluminum magnesium manganese color-coated plates can achieve a wide variety of appearances through different surface treatment processes and coating colors. It can showcase the texture of metallic luster, and also imitate the appearance of other materials (such as wood and stone).

-

Aluminum magnesium manganese color-coated steel plate

Aluminum magnesium manganese color-coated plates can achieve a wide variety of appearances through different surface treatment processes and coating colors.

-

Aluminum magnesium manganese color-coated steel plate

Aluminum magnesium manganese color-coated plates are lightweight, high-strength, corrosion-resistant, and waterproof, making them widely used in roofing projects for various buildings, such as stadiums, exhibition centers, airport terminals, and train stations.

-

Fluorocarbon coated color steel plate (wood grain)

PVDF fluorocarbon coating is the best among existing building coatings. As a recognized organic coating with the best protective function, it protects metal building panels from damage and maintains its bright color for decades.

-

Fluorocarbon coated aluminum sheet

The PVDF coating on the steel sheet is made of polyvinylidene fluoride, a highly durable and weather-resistant material. This coating is highly resistant to ultraviolet light, moisture, and other environmental factors, making it suitable for both indoor and outdoor applications.

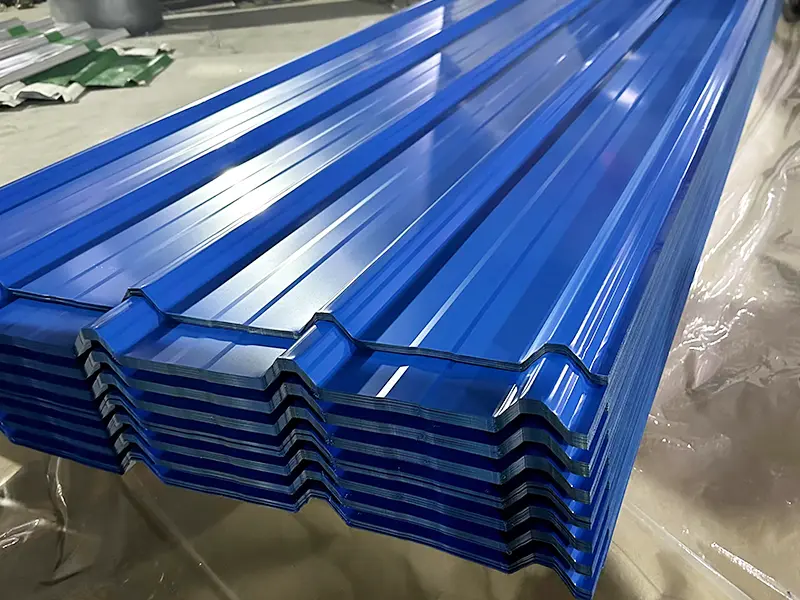

Color Steel Tile

-

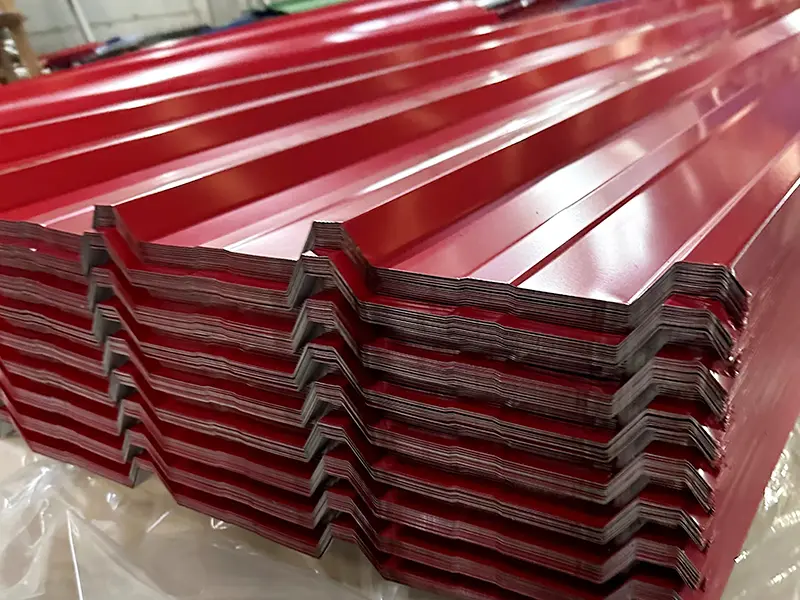

Color corrugated tile

The characteristics of profiled steel sheets are high density, high strength, and long lifespan. They remain stable under various extreme weather conditions.

-

Color corrugated tile

Roof tiles can be made from a variety of materials, such as concrete, metal (especially steel), and ceramic. In metal roof tiles, especially those made of pressed color-coated steel, the manufacturing process includes steps such as pressing thin steel sheets, coating, drying, forming, and trimming.

-

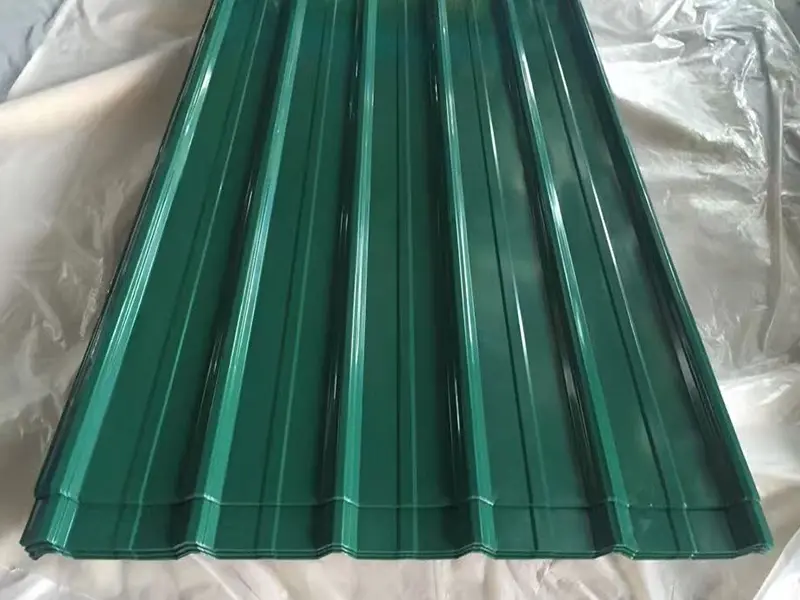

Corrugated roofing sheet

The profiled steel sheet boasts excellent compressive, bending, wind, and earthquake resistance, features a long lifespan, good weather resistance, and can adapt to various climatic conditions. In addition, profiled steel sheets are easy to install, have high construction efficiency, and low maintenance costs.

-

Color-coated pressed tile

In the industrial field, profiled steel sheets are commonly used in the construction of factories, warehouses, and workshops. In civil construction, in addition to roof and exterior wall coverings, profiled steel sheets can also be used as building materials for carports, garden sheds, etc.

-

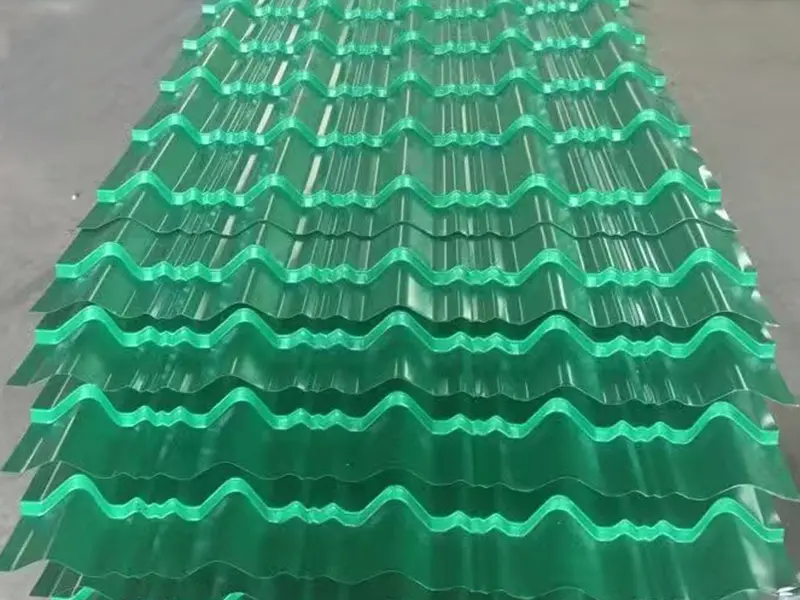

Color corrugated tile

The characteristics of profiled steel sheets are high density, high strength, and long lifespan. They remain stable under various extreme weather conditions.

-

Color corrugated tile

The characteristics of profiled steel sheets are high density, high strength, and long lifespan. They remain stable under various extreme weather conditions.

-

Color corrugated tile

The characteristics of profiled steel sheets are high density, high strength, and long lifespan. They remain stable under various extreme weather conditions.

-

Color corrugated tile

The characteristics of profiled steel sheets are high density, high strength, and long lifespan. They remain stable under various extreme weather conditions.

Printed Color Coated Sheets

-

Color printing plate

Printed PPGI, PPGL and steel sheets are specialized building materials with attractive patterns and textures. They are pre-coated metal sheets used for roofing, wall cladding, ceilings, and interior and exterior decoration.

-

Color printing plate

PPGI and PPGL use protective polymer coatings such as polyester, silicone-modified polyester, and polyvinylidene fluoride. These coatings provide superior weather resistance, UV protection, corrosion resistance, and lasting color. Vivid patterns are printed on the coating to create unique visual effects.

-

Color printing plate

Printed PPGI, PPGL and steel sheets are specialized building materials with attractive patterns and textures. They are pre-coated metal sheets used for roofing, wall cladding, ceilings, and interior and exterior decoration.

-

Color printing plate

Printed PPGI, PPGL and steel sheets are specialized building materials with attractive patterns and textures. They are pre-coated metal sheets used for roofing, wall cladding, ceilings, and interior and exterior decoration.

-

Color printing plate

Printed PPGI, PPGL and steel sheets are specialized building materials with attractive patterns and textures. They are pre-coated metal sheets used for roofing, wall cladding, ceilings, and interior and exterior decoration.

-

Color printing plate

Printed PPGI, PPGL and steel sheets are specialized building materials with attractive patterns and textures. They are pre-coated metal sheets used for roofing, wall cladding, ceilings, and interior and exterior decoration.

-

Color printing plate

Printed PPGI, PPGL and steel sheets are specialized building materials with attractive patterns and textures. They are pre-coated metal sheets used for roofing, wall cladding, ceilings, and interior and exterior decoration.

-

Color printing plate

Printed PPGI, PPGL and steel sheets are specialized building materials with attractive patterns and textures. They are pre-coated metal sheets used for roofing, wall cladding, ceilings, and interior and exterior decoration.

-

Color printing plate

Printed PPGI, PPGL and steel sheets are specialized building materials with attractive patterns and textures. They are pre-coated metal sheets used for roofing, wall cladding, ceilings, and interior and exterior decoration.

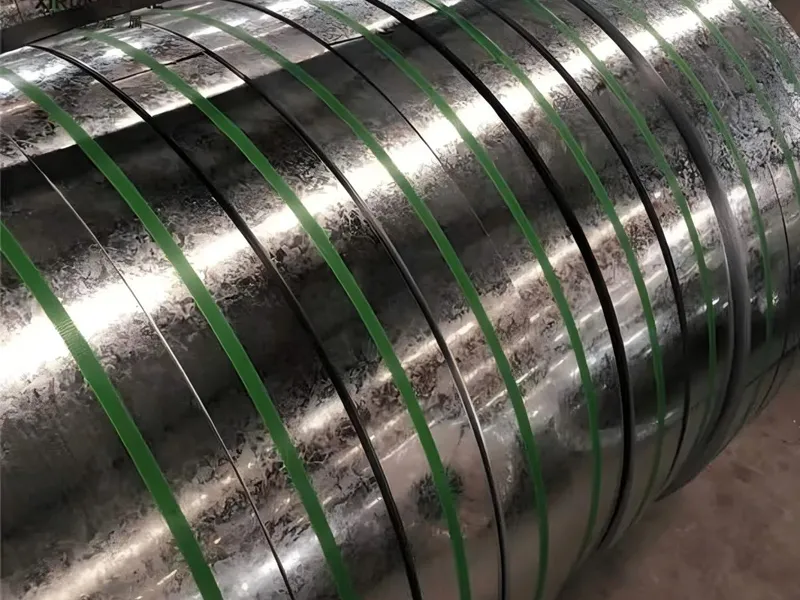

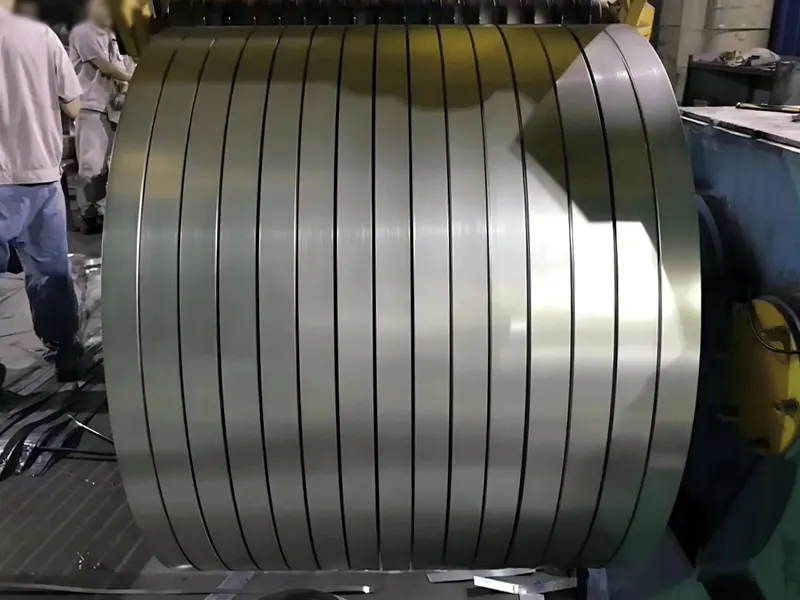

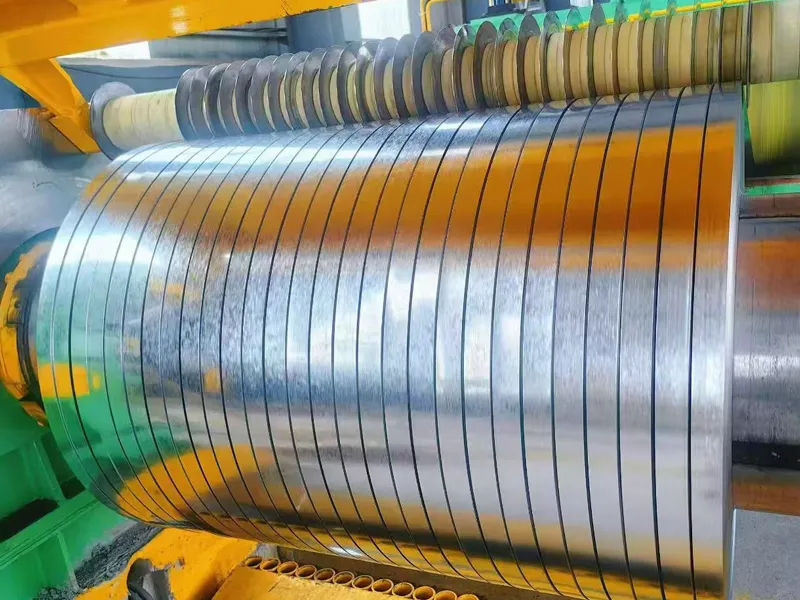

Strip steel

-

Galvanized Steel Strip

Hot-dip galvanized steel sheets feature a smooth, aesthetically pleasing surface and are widely used in industries such as pre-coated baseboards, construction, household appliances, automotive manufacturing, and container production.

-

Strip steel

Hot-dip galvanized steel sheets feature a smooth, aesthetically pleasing surface and are widely used in industries such as pre-coated baseboards, construction, household appliances, automotive manufacturing, and container production.

-

Strip steel

Hot-dip galvanized steel sheets feature a smooth, aesthetically pleasing surface and are widely used in industries such as pre-coated baseboards, construction, household appliances, automotive manufacturing, and container production.

-

Strip steel

Hot-dip galvanized steel sheets feature a smooth, aesthetically pleasing surface and are widely used in industries such as pre-coated baseboards, construction, household appliances, automotive manufacturing, and container production.

-

Strip steel

Hot-dip galvanized steel sheets feature a smooth, aesthetically pleasing surface and are widely used in industries such as pre-coated baseboards, construction, household appliances, automotive manufacturing, and container production.

-

Strip steel

Hot-dip galvanized steel sheets feature a smooth, aesthetically pleasing surface and are widely used in industries such as pre-coated baseboards, construction, household appliances, automotive manufacturing, and container production.

-

Strip steel

Hot-dip galvanized steel sheets feature a smooth, aesthetically pleasing surface and are widely used in industries such as pre-coated baseboards, construction, household appliances, automotive manufacturing, and container production.

-

Strip steel

Hot-dip galvanized steel sheets feature a smooth, aesthetically pleasing surface and are widely used in industries such as pre-coated baseboards, construction, household appliances, automotive manufacturing, and container production.