Reference | Interpretation of the second half market based on silicon steel supply and demand

Category: Industry News

Time:2025-08-28

Overview: Reviewing the first half of 2025, China's silicon steel market showed a pattern of strong supply and weak demand, with spot prices continuously declining. From the price trend perspective, after a rapid price increase last September, the lowest price point in the first half of the year fell below last year's low. Since the beginning of this year, except for a slight rebound in late May due to a brief boost from new energy demand, the overall trend remained downward. Demand in other sectors showed little concentrated release, and the silicon steel industry experienced a "peak season without peak" trend. Fundamentally, supply continued to grow in the first half of the year, private enterprises saw a decline in production profits, silicon steel foreign trade volume remained acceptable, and total inventory slightly decreased. Under the premise that demand could not be effectively released, there was significant upward pressure on silicon steel market prices. Looking ahead to the second half of the year, where will China's silicon steel market head? This article will analyze based on industry fundamentals, macro conditions, and other aspects.

Overview: Reviewing the first half of 2025, China's silicon steel market showed a pattern of strong supply and weak demand, with spot prices continuously declining. From the price trend perspective, after a rapid price surge last September, the lowest price in the first half of the year fell below last year's low point. Since the beginning of this year, except for a slight rebound in late May due to a brief boost from new energy demand, the overall trend remained downward. Demand in other sectors showed little concentrated release, and the silicon steel industry experienced a "peak season without peak" trend. Fundamentally, supply continued to grow in the first half, private enterprises' production profits declined, foreign trade volume of silicon steel remained acceptable, and total inventory slightly decreased. Under the premise that demand could not be effectively released, there was significant upward pressure on silicon steel market prices. Looking ahead to the second half, where will China's silicon steel market head? This article will analyze based on industry fundamentals and macro conditions.

1. Price Fluctuated Downward in the First Half, Brand Price Differences Fluctuated Significantly

As of June 30, the Mysteel non-oriented silicon steel 800 grade price index was 4409.66 points, down 15.28% year-on-year. Regarding spot prices, according to Mysteel data, the average price of non-oriented silicon steel 800 grade in 13 cities nationwide was 4369 yuan/ton, down 13.7% year-on-year; the average price of non-oriented silicon steel 300 grade was 6034 yuan/ton, down 8.2% year-on-year.

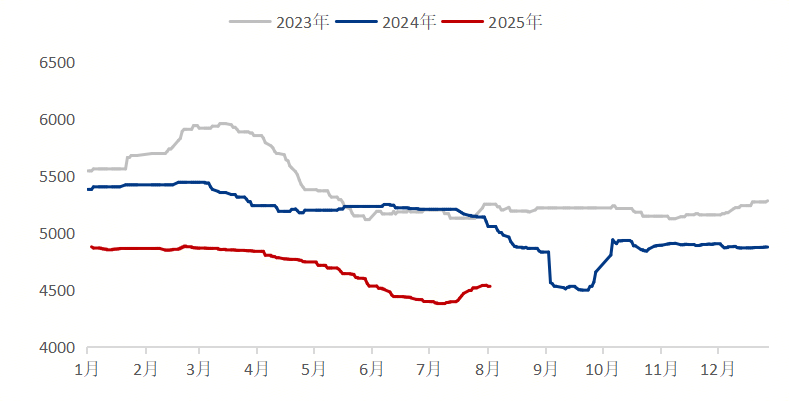

Figure 1: Absolute Price Index Trend of Non-Oriented Silicon Steel (Unit: yuan/ton)

Data Source: Steel Union Data

In 2024, domestic silicon steel showed a high start and low finish throughout the year, with the price center further moving downward, rebounding from an oversold state in September to November. From January to April 2025, non-oriented silicon steel spot prices fluctuated within a narrow range, and prices gradually weakened starting in May. As of June 30, the national average price had cumulatively dropped by 479 yuan/ton, state-owned enterprise resources dropped by 400 yuan/ton, and private enterprise resources dropped by 600 yuan/ton.

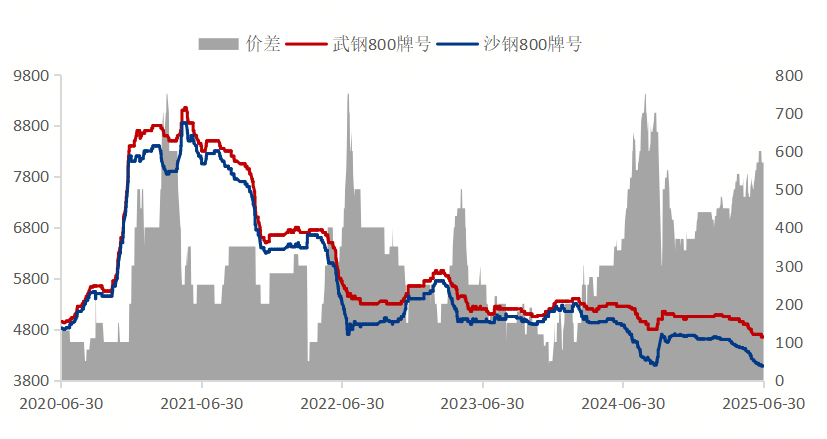

Figure 2: Price Difference Between State-Owned and Private Enterprises for Non-Oriented Silicon Steel in Recent Years (Unit: yuan/ton)

Data Source: Steel Union Data

From the trend of price differences between state-owned and private enterprises, the price gap of spot resources between them has widened. As of June 30, the average price difference between WISCO and Shagang was at least 370 yuan/ton and at most 600 yuan/ton, with an average price difference of 480 yuan/ton in the first half, expanding by 248 yuan/ton year-on-year. The average price difference trend over the past two years basically shows a process of first widening, then narrowing, and then widening again. According to market traders' feedback, market demand this year was poor, state-owned enterprise resource circulation orders were cautious, and traders ordered little, mostly for end-user stockpiling. State-owned enterprise resource spot prices remained relatively firm, while private enterprise resources circulated more. Under the increased expectation of price declines, traders mainly sold at low prices early on, resulting in more significant price fluctuations.

2. Raw Materials - High Costs of Silicon Steel Hot Rolls and Silicon Steel Cold Rolled Coils

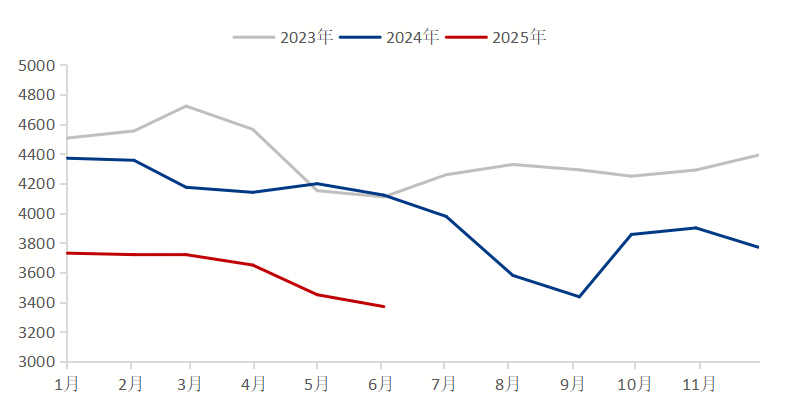

In recent years, the trend of silicon steel hot rolling has generally been downward. According to survey data as of June, the ex-factory price of silicon steel hot rolls was 3383 yuan/ton, down 738 yuan/ton year-on-year. The average ex-factory price in the first half was 3614 yuan/ton, down 843 yuan/ton year-on-year. Feedback from most supplying enterprises indicates that silicon steel hot rolling usually adds about 300 yuan/ton compared to general hot rolling. Short-process silicon steel producers reported that raw material prices were generally high this year.

Figure 3: Comprehensive Price Trend of Domestic Non-Oriented Silicon Steel Hot Rolls 800 Grade (Unit: yuan/ton)

Data Source: Steel Union Data

3. Production Costs - Significant Profit Decline in Private Enterprises

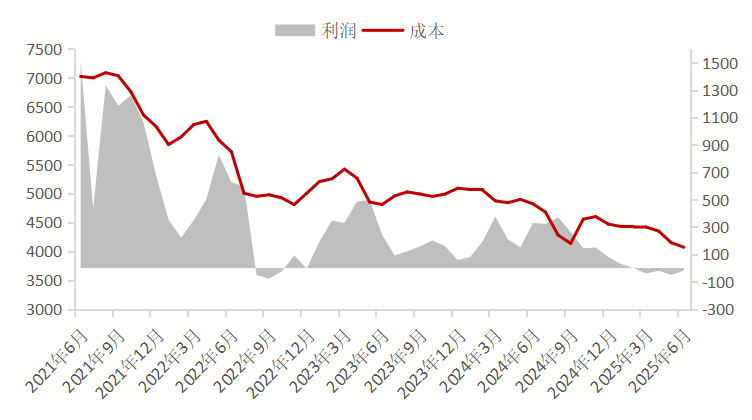

From the cost-profit trend, domestic private silicon steel processing enterprises have shown a continuous profit decline in recent years. Survey and estimation data as of June show that the average production cost for domestic private enterprises was 4070 yuan/ton, down 751 yuan/ton year-on-year, with an average gross profit of -20 yuan/ton, down 348 yuan/ton year-on-year. Short-process silicon steel producers are basically at the breakeven point, whereas profits were maintained around 200 yuan/ton in the first half of last year. On one hand, since the first half of this year, due to high costs of silicon steel hot rolling and cold rolled coils, and gradual release of low and medium grade non-oriented silicon steel capacity, market competition has been fierce, and enterprises continuously lowered prices to secure orders. On the other hand, processing costs have increased significantly compared to last year. According to some purchasers of silicon steel cold rolled coils, processing costs per ton of steel have gradually risen from about 300 yuan to 400 yuan this year, with both raw material cold rolled coil and processing costs increasing, raising operating costs.

Figure 4: Cost and Profit Estimation of Short-Process Non-Oriented Silicon Steel Production (Unit: yuan/ton)

Data Source: Steel Union Data

4. Supply - Domestic Non-Oriented Silicon Steel Supply Increased by 2.5% in the First Half

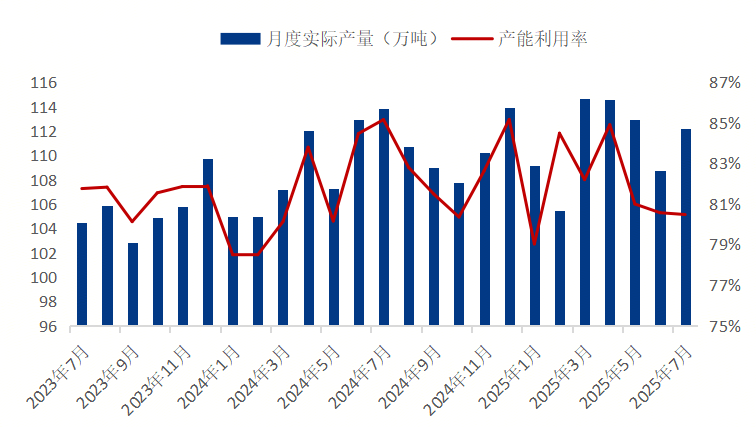

According to Mysteel's survey of 29 production enterprises, from January to June, China's non-oriented silicon steel output totaled 6.6578 million tons, a year-on-year increase of 2.5%, with an average capacity utilization rate of 82%. Among them, high-grade output totaled 2.5222 million tons, accounting for 37.85% of non-oriented silicon steel. In July, actual non-oriented silicon steel output was 1.1224 million tons, a month-on-month increase of 35,100 tons. Currently, domestic non-oriented silicon steel supply continues to remain high.

Figure 5: National Non-Oriented Silicon Steel Production Situation (Unit: 10,000 tons)

Data Source: Steel Union Data

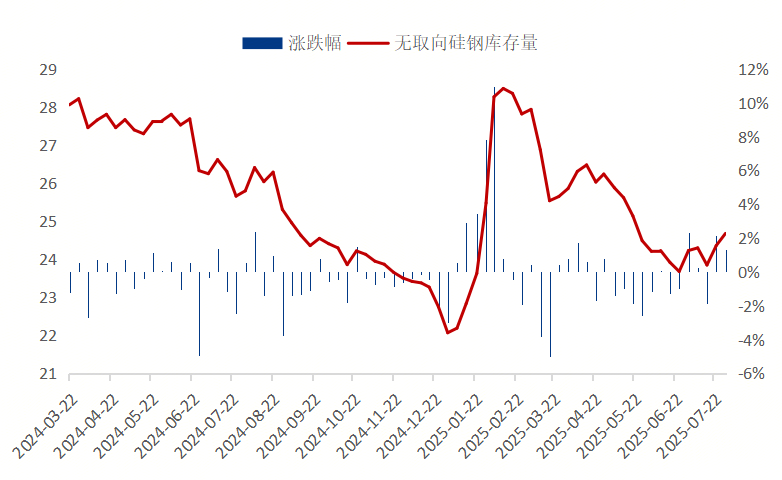

5. Inventory - Non-Oriented Silicon Steel Continues Slight Decline

Mysteel monitors inventory in 21 cities. In the last week of July, total social inventory of non-oriented silicon steel was 246,800 tons, a month-on-month increase of 10,000 tons; factory inventory was 136,600 tons, a month-on-month decrease of 800 tons. Total inventory was 383,400 tons, a month-on-month increase of 9,200 tons. From the social inventory trend, the peak accumulation was in mid-February this year, followed by continuous inventory reduction. According to market feedback, traders' sentiment this year is cautious, and compared to past years, overall inventory has decreased by about 20%.

Figure 6: Inventory Situation of Non-Oriented Silicon Steel in 21 Cities Nationwide (Unit: 10,000 tons)

Data Source: Steel Union Data

6. Import and Export - Significant Year-on-Year Growth in Oriented Silicon Steel Exports in the First Half

Customs data shows that in 2024, China's total silicon steel exports were 1.4472 million tons, and imports were 148,900 tons, with exports accounting for about 9% of China's total silicon steel supply. From January to June 2025, non-oriented silicon steel cumulative exports were 372,700 tons, down 2.5% year-on-year; oriented silicon steel cumulative exports were 393,200 tons, up 24.7% year-on-year. From January to June 2025, non-oriented silicon steel cumulative imports were 29,300 tons, down 31% year-on-year; oriented silicon steel cumulative imports were 47,100 tons, up 31.2% year-on-year.

The significant growth in oriented silicon steel exports in the first half of the year is mainly due to the following factors: First, market opportunities brought by global energy efficiency upgrades. Insufficient local manufacturing capacity in Europe and the US has led to a surge in demand for high-grade oriented silicon steel, creating favorable conditions for exports from China; China's high-grade oriented silicon steel (such as HiB steel) magnetic performance is close to international advanced levels, with obvious cost-performance advantages. Second, support from domestic policies and industrial upgrades. The "dual carbon" policy drives demand growth for ultra-high voltage transformers and new energy equipment, boosting exports of high-grade products; domestic substitution accelerates, with imports of oriented silicon steel decreasing from 237,400 tons in 2012 to 73,000 tons in 2024, and domestic capacity shifting to international markets. Finally, structural changes in supply and demand. This year, domestic oriented silicon steel capacity expansion and price competitiveness, coupled with relatively saturated domestic ultra-high voltage transmission and transformation station demand, have led to high supply pressure and foreign trade promoting demand release.

7. Downstream Demand Situation

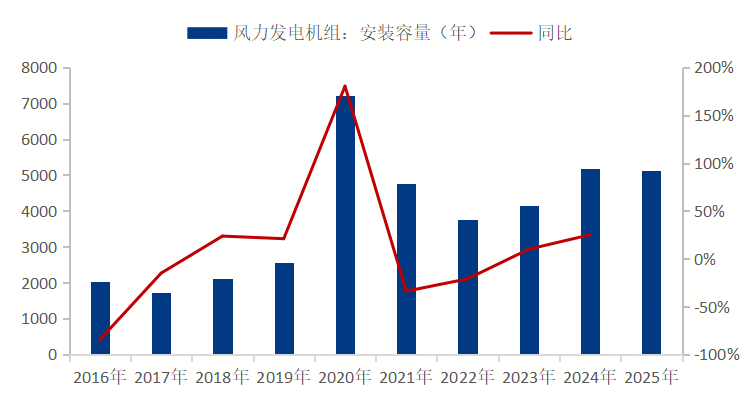

1. Generator output increased by 63% year-on-year, domestic newly added cumulative installed capacity of wind turbines increased by 98.88% year-on-year, while wind turbine exports declined by 14.1% year-on-year. According to data from the National Bureau of Statistics, from January to June 2025, China's cumulative generator output was 139.445 million kilowatts, a 63% increase compared to the same period last year. According to the National Energy Administration, from January to June 2025, China's cumulative installed capacity of wind turbines was 51.39 million kilowatts, a 98.88% increase year-on-year. According to the General Administration of Customs, from January to June 2025, China exported a cumulative total of 24,309 wind turbines, a 14.1% decrease year-on-year.

Figure 7: Changes in Installed Capacity of Wind Turbines in China (Unit: 10,000 kilowatts, %)

Data Source: Steel Union Data

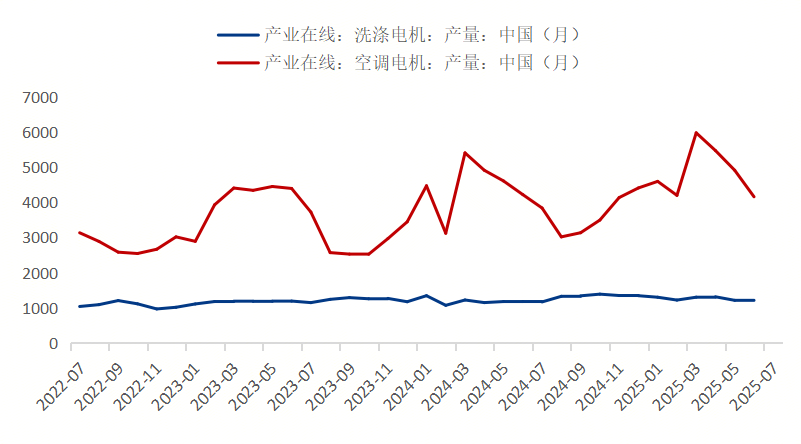

2. Production of washing machine motors and air conditioner motors both increased in the first half of the year. According to data from Industry Online, from January to June 2025, China's cumulative production of washing machine motors was 75.426 million units, a 5.81% increase year-on-year; air conditioner motor production was 293.05 million units, an 8.79% increase year-on-year.

Figure 8: Monthly Motor Production (Unit: 10,000 units)

Data Source: Steel Union Data

3. Significant increase in compressor production and sales. According to Industry Online data, from January to June 2025, China's cumulative production of rotary compressors was 167.665 million units, a 10.5% increase year-on-year; cumulative sales of rotary compressors were 170.028 million units, a 7.3% increase year-on-year.

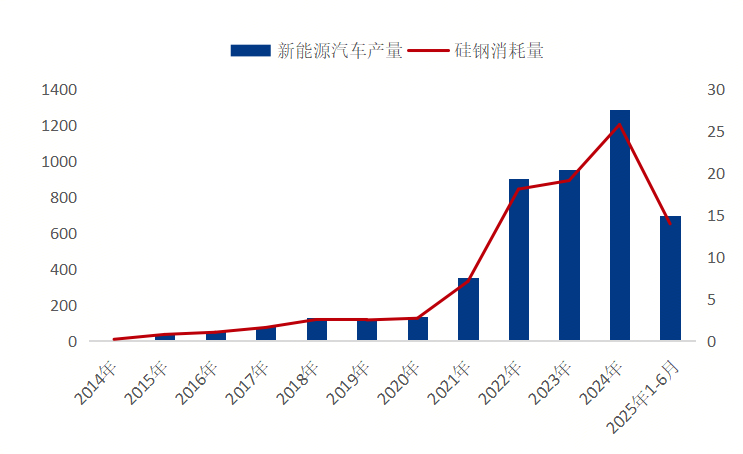

4. Significant growth rate in new energy vehicle production. According to data from the China Association of Automobile Manufacturers, from January to June 2025, China's cumulative production of new energy vehicles was 6.9691 million units, a 40.9% increase year-on-year. According to Mysteel estimates, the new energy vehicle industry consumed about 140,000 tons of high-end non-oriented silicon steel in the first half of the year.

Figure 9: New Energy Vehicle Production and Silicon Steel Demand (Unit: 10,000 units, 10,000 tons)

Data Source: China Association of Automobile Manufacturers, Mysteel

5. The home appliance industry maintained steady growth in some areas in the first half of the year. According to the National Bureau of Statistics, in June 2025, China's air conditioner production was 28.383 million units, a 3.0% year-on-year increase; cumulative production from January to June was 163.296 million units, a 5.5% increase year-on-year. Refrigerator production in June was 9.047 million units, a 4.8% increase year-on-year; cumulative production from January to June was 50.642 million units, flat year-on-year. Washing machine production in June was 9.508 million units, a 16.5% increase year-on-year; cumulative production from January to June was 58.604 million units, a 10.3% increase year-on-year. Color TV production in June was 16.252 million units, an 11.1% decrease year-on-year; cumulative production from January to June was 91.871 million units, a 5.5% decrease year-on-year.

8. Market Outlook

Macro: In the second half of 2025, the global economy will continue to slow down, with trade policy becoming a key variable. Global GDP growth is expected to slow to 2.8%. The bulk commodity market shows a "weak demand + high supply" main theme. Oversupplied varieties are under pressure; ferrous metal commodities are constrained by a supply-strong and demand-weak pattern and will continue to decline, although with changes in China's domestic risk appetite and liquidity, the downward trend may occasionally slow or present structural rebound opportunities. China's economy shows short-term resilience, but the sustainability of export resilience is uncertain. China's fiscal focus is on "two new" (new energy and new infrastructure), but the offsetting effect on export decline may be limited. However, caution is needed against spillover from geopolitical conflicts and liquidity shocks from US debt maturities, which could increase commodity price volatility.

Supply: Domestic silicon steel supply may see significant growth in the second half of the year. Capacity from enterprises that started production in the first half will be further released, and many enterprises will add new production in the second half. Annual dynamic production of non-oriented silicon steel is expected to grow by about 10%.

Demand: During the "Golden September and Silver October" period, domestic silicon steel demand has further room for release. The three major white goods and automotive industries maintain steady production and sales growth; industrial motors perform poorly, and the growth space for silicon steel foreign trade is limited. In home appliances, the subsidy scope for trade-in has expanded from 8 to 12 categories, adding new categories such as water purifiers and dishwashers, with subsidy rates maintained at 15%-20% of the selling price. However, note that the remaining central subsidy funds of 138 billion yuan in the second half will be strictly limited, possibly causing adjustments in subsidy disbursement pace; high-end home appliance demand in fourth-tier cities grows by 25%, with significant three-generation simultaneous consumption characteristics, and smart home appliance penetration exceeds 40%. In the automotive sector, with continuous new model releases and technological innovation, the "reshuffle" in the new energy vehicle market will accelerate, and those who can accurately grasp user needs and maintain technological leadership will ultimately stand out.

Cost & Profit: Profits for major steel varieties may shrink somewhat in the early second half, mainly due to gradual increases in carbon and iron element costs in furnace materials, with silicon steel costs also having room to rise. For full-process silicon steel producers, profits will remain acceptable to some extent, while private small factories, constrained by high costs of raw material silicon steel hot rolling and hard rolling, may maintain slight fluctuations around breakeven in the second half or longer term.

Price: From the fundamentals, non-oriented silicon steel is expected to show a rise followed by a decline in the second half. Factors restricting domestic silicon steel prices include: first, the bearish point remains the persistent supply-demand imbalance of silicon steel, with continuous capacity expansion in recent years, small demand volume in the high-end industry, fierce competition in the mid-to-low-end industry, and limited growth in non-oriented silicon steel exports. Second, current market price fluctuations overly depend on futures market expectations, making spot prices hard to keep up, with a significant narrowing of the futures-spot spread, leading to periodic "priced but no market" situations. Finally, the bullish points include raw material cost support, current price levels being relatively low, and optimistic expectations for the traditional "Golden September and Silver October" peak season sentiment. Therefore, the domestic non-oriented silicon steel peak in the second half is expected to appear during "Golden September and Silver October," followed by a gradual decline.

Keywords: Reference | Interpretation of the second half market based on silicon steel supply and demand

Related Information

Company News

-

Chuangcai’s latest news: Trump puts further pressure on Iran, and coke prices see their first round of increase.

Time:2026-01-29

-

We warmly welcome UAE customers to visit our color-coated and galvanized steel plants.

Time:2026-01-27

-

Warmly celebrate that our Nepalese customer has successfully passed the inspection of all company products.

Time:2026-01-23

-

Chuangcai Group Co., Ltd. launches bright-finish galvanized steel sheets, leading the industry with advanced technology and superior quality.

Time:2026-01-14

-

Warm Celebration of the First Perfect Cooperation between Chuangcai Group Co., Ltd. and Azerbaijani Customers

Time:2025-12-16

-

Warmly celebrate the great success of Chuangcai Group Co., Ltd. at the Dubai exhibition.

Time:2025-12-02

-

Morning reading: The "14th Five-Year" Plan proposal clearly outlines the development direction and opportunities for the steel industry.

Time:2025-10-29

-

Special Meeting on Creative Color Group Corporation's Strategy for Managing Risks in the Indian Market

Time:2025-10-16

-

Warmly celebrate Chuangcai Group Co., Ltd.'s successful participation in Alibaba International's "Heroes Contest, Billion Battle to Fame" high-quality customer negotiation training.

Time:2025-09-15

-

Morning Reading: Iron ore prices rise above $105, first round of coke price reductions implemented

Time:2025-09-09

-

Warmly celebrate Shandong Longjian Board Industry Co., Ltd. for successfully passing the ISO9001 certification

Time:2025-09-05

-

Internal Company International Business Knowledge Collision: Wisdom Integration, Expanding Global Perspectives Together

Time:2025-09-02

-

Two groups of Indian clients visited the factory, securing 3.000 tons of new orders

Time:2025-08-15

-

What industries use galvanized steel sheets? What types are there?

Time:2025-01-08

-

What are the main applications of galvanized materials?

Time:2025-01-08

-

How to distinguish between galvanized sheet and cold-rolled sheet

Time:2025-01-08

-

The difference between galvanized steel sheet and cold-rolled steel sheet

Time:2025-01-08

Industry News

-

Chuangcai’s Interpretation: The Fed’s Future Policy Direction Still Holds Uncertainty—A Brief Analysis of “Interest Rate Cuts, Balance Sheet Reduction, and a Stable U.S. Dollar”

Time:2026-02-03

-

The global precious metals market plunges; China’s Hubei steel mills conduct winter stockpiling surveys.

Time:2026-02-02

-

Chuangcai Latest News: Supply Increase and Demand Decrease for China's Five Major Steel Products, Chief Outlook on February Steel Prices

Time:2026-01-30

-

China Iron and Steel Association: Production Status of Plate and Strip Products from Key Statistical Enterprises as of December 2025

Time:2026-01-28

-

ChuangCai Consulting: Global crude steel production is projected to reach 1849 million tons in 2025, with a general rise in international commodity prices.

Time:2026-01-26

-

What structural changes will occur in China’s steel demand in 2026?

Time:2026-01-23

-

In the fourth quarter of 2025, Fortescue Metals Group in Australia is expected to produce 49.8 million tons of iron ore, a 2% decrease year-on-year.

Time:2026-01-22

-

This year, the enthusiasm for winter stockpiling of construction steel in Shandong Province, China, has cooled down, and winter inventories will continue to decline.

Time:2026-01-21

-

In 2025, China exported 6,690 ships, a year-on-year increase of 16.2%.

Time:2026-01-19

-

International commodity prices are rising across the board, and several countries are urging their citizens to leave Iran.

Time:2026-01-15

-

China’s latest advisory news: Trump says he’s canceling all talks with Iranian officials; steel futures rise in overnight trading.

Time:2026-01-14

-

China Shagang’s scrap steel prices rise by 50 yuan; China Ansteel, Bensteel, and Linggang announce February price adjustments.

Time:2026-01-13

-

The State Council executive meeting deploys policies to boost domestic demand; Zhongtian Steel and Yonggang announce their latest price adjustments.

Time:2026-01-12

-

Pressure Eases, Resilience Remains—A Forecast of the Impact of Global Steel Trade Remedies on China in 2026

Time:2026-01-09

-

Steel has it all wrapped up at the Northeastern University EXP Building in Boston

Time:2026-01-08

-

Steel-Based Zero Energy Building (ZEB) Inaugurated in India

Time:2026-01-07

-

International bulk commodities generally surged, while black commodity futures fell during the night session.

Time:2026-01-06

-

As the price pattern shifts to a narrowing “W” formation and regional coordination strengthens, can the 2026 stainless steel market maintain steady progress?

Time:2026-01-06

-

January cold-rolled prices may trend weaker.

Time:2026-01-06

-

January Steel Market—Pre-Holiday Weak Realities Weigh Down Prices; Black-Steel Sector Awaits “Spring Surge”

Time:2025-12-29

-

Interpreting the Guidance of Import Coal Price Spreads on Domestic Coking Coal Price Volatility (Part 1)

Time:2025-12-29

-

2026 Steel Market Winter Stockpiling Outlook

Time:2025-12-25

-

The countdown for export licenses has begun! Can China’s galvanized sheet exports reach new highs again in 2026?

Time:2025-12-25

-

Li Qiang called for planning a batch of major projects and undertakings that can drive the overall situation.

Time:2025-12-23

-

Value Equilibrium—A 2026 Outlook for China’s Steel Market

Time:2025-12-22

-

The Ministry of Commerce responds to the management of steel export licenses, and Jiangsu’s winter stockpiling of scrap steel shrinks in scale.

Time:2025-12-20

-

2026 Steel Indirect Export Forecast

Time:2025-12-18

-

Analysis of the Impact of Implementing Export License Management for Seamless Pipe Products and Enterprises’ Response Strategies

Time:2025-12-18

-

Luo Tiejun calls for jointly breaking the cycle of involutionary competition; the chief analyst of sheet and strip forecasts January steel prices.

Time:2025-12-16

-

Multiple ministries are promoting measures to combat “involution”; interpretation of the management of steel export licenses.

Time:2025-12-16

-

The Federal Reserve cut interest rates by 25 basis points, while Zhongtian rebar prices were raised by 50 yuan.

Time:2025-12-11

-

During the 14th Five-Year Plan, China’s steel industry is exploring a path toward reducing output while improving quality.

Time:2025-12-11

-

Multiple regions have activated emergency responses for severe pollution, and the scale of maintenance at steel mills has expanded.

Time:2025-12-11

-

Summary of the Jiangsu Steel Industry Chain Access White List; Shortage of Building Materials Specifications in Yunnan and Guizhou

Time:2025-12-03

-

Steel mills are expanding the scale of production cuts and maintenance, and steel billets in Tangshan rose over the weekend.

Time:2025-12-01

-

The NDRC is promoting measures to address disorderly price competition; this week, steel supply has increased while demand has declined.

Time:2025-12-01

-

Iron ore prices surged above $105, and the yuan-to-dollar exchange rate hit a more than one-year high.

Time:2025-11-27

-

Xi Jinping Holds Telephone Conversation with Trump; International Commodity Prices Rise

Time:2025-11-27

-

Several Federal Reserve officials signaled potential interest rate cuts, while Shagang's scrap steel prices were lowered.

Time:2025-11-24

-

Black futures fell in the night session, with electric furnace steel mills posting a loss of 117 yuan per ton.

Time:2025-11-20

-

International commodity prices fell across the board, while five steel mills raised their prices.

Time:2025-11-18

-

More construction material steel plants have resumed production, and inspection teams will gradually begin operations in the Beijing-Tianjin-Hebei region.

Time:2025-11-17

-

Black futures fell during the night trading session, as the Simandou iron ore project will gradually ramp up its production capacity.

Time:2025-11-13

-

Xinjiang steel plants reduce production during winter maintenance, while the U.S. temporarily suspends its export control rules on penetrating technologies.

Time:2025-11-12

-

In December, Baowu Steel raised prices amid a general rise in international commodity markets.

Time:2025-11-12

-

Supply and demand for the five major steel products both declined, with electric furnaces incurring a loss of 167 yuan per ton of steel.

Time:2025-11-07

-

Steel prices remained stable overall, while coking coal futures rose by more than 1%.

Time:2025-11-06

-

The Drivers Behind China's High Growth in Steel Exports and the Resulting Structural Changes

Time:2025-11-05

-

Morning Reading: 84 New Enterprises Proposed for Entry into Scrap Steel Processing, Baosteel Adjusts Production Capacity Goals

Time:2025-11-04

-

Morning Reading: The Ministry of Commerce Highlights the Consensus Reached in China-U.S. Economic and Trade Talks, While 6 Steel Mills Raise Prices

Time:2025-10-31

-

Morning Read: China-U.S. Leaders to Hold Meeting, Fed Cuts Interest Rate by 25 Basis Points

Time:2025-10-30

-

Morning Read: "One Line, One Bureau, One Meeting" Makes a Strong Statement—Black Futures Turn Positive in Overnight Trading

Time:2025-10-28

-

Morning Read: China and the U.S. Reach Preliminary Consensus; Draft Opinions Sought on New Steel Capacity Replacement Plans

Time:2025-10-27

-

Morning Read: International commodity prices surged across the board, while supply and demand for the five major steel products both increased.

Time:2025-10-24

-

In the third quarter of 2025, Fortescue's iron ore production reached 50.8 million tons, representing a year-on-year increase of 6%.

Time:2025-10-23

-

Steel prices remain stagnant as the market awaits a breakthrough in macroeconomic conditions.

Time:2025-10-22

-

Morning Reading: China and the U.S. Agree to Hold a New Round of Economic and Trade Consultations; Steel Mills Reduce Production and Conduct Maintenance Inspections

Time:2025-10-20

-

Morning Reading: Sichuan's Steel Industry Advances Measures to Combat "Involution," While Several Steel Mills in Northern China Undertake Maintenance Overhauls.

Time:2025-10-16

-

Morning Reading: China Responds to U.S. Threat of Additional Tariffs on China, October North-to-South Steel Material Survey

Time:2025-10-13

-

Morning Reading: Two Departments Take Action to Address Unregulated Price Competition, Black Commodity Futures Turn Positive in Overnight Trading

Time:2025-10-10

-

Morning Reading: Steel inventories surged by 1.28 million tons during the holiday period; summary of performance for black commodity sectors

Time:2025-10-09

-

Morning reading: The State-owned Assets Supervision and Administration Commission urges central enterprises to take the lead in "fighting internal involution," as rebar prices fall below 3,100.

Time:2025-09-28

-

Morning Reading: Ministry of Commerce Counterattacks Mexico's China-Related Measures; Supply and Demand Both Rise for Five Major Steel Products

Time:2025-09-26

-

After the National Day holiday, the price of hot-rolled strip steel in China may rise first and then decline

Time:2025-09-25

-

South Korea's K-Steel bill is impacting our country's steel exports, and the three major coal import ports will shut down.

Time:2025-09-24

-

Black Metal Regular Meeting: This week, the steel market showed mixed trends, while raw materials may remain relatively strong.

Time:2025-09-23

-

Midday Report: Steel prices mainly rose, with coking coal futures climbing more than 5%.

Time:2025-09-16

-

A Brief Analysis of Profit Contraction Pressure on Domestic Tinplate Manufacturers

Time:2025-09-15

-

Afternoon Report: Localized Steel Price Increase, Iron Ore Futures Drop Over 1%

Time:2025-09-11

-

Morning reading: Latest survey on steel mill maintenance impact, structural steel production capacity adjustment enters a stable period

Time:2025-09-08

-

Morning reading: Tangshan Steel Plant resumes production in batches, Trump signs US-Japan trade agreement

Time:2025-09-05

-

Morning reading: Black futures declined in the night session, construction sites in Beijing-Tianjin-Hebei gradually resume work

Time:2025-09-04

-

The Breakthrough Path for Steel Enterprises under the Transformation and Upgrading of the Construction Industry

Time:2025-09-03

-

The steel market still has room to decline in September

Time:2025-09-02

-

Anti-dumping situation of foreign steel products against China from January to August

Time:2025-09-01

-

The European Union plans to eliminate tariffs on American industrial goods to alleviate the impact of car tariffs.

Time:2025-08-29

-

Reference | Interpretation of the second half market based on silicon steel supply and demand

Time:2025-08-28

-

WEEKLY SUMMARY: China's steel market slides on weak fundamentals

Time:2025-08-25

-

WEEKLY: Chinese mills' steel stocks edge down

Time:2025-08-22

-

Việt Nam imposes anti-dumping duties on Chinese and South Korean coated steel

Time:2025-08-19

-

Vietnam imposes AD duties on galvanized steel from China, South Korea

Time:2025-08-19

-

Detailed explanation of color-coated steel sheet types, colors, and applications

Time:2025-02-27

-

What is cold-rolled sheet material? A comprehensive analysis of the characteristics and applications of cold-rolled sheet.

Time:2025-01-08

-

Advantages and Applications of Cold-Rolled Sheet

Time:2025-01-08

-

Applications and characteristics of color-coated steel sheets

Time:2025-01-08

-

Detailed explanation of the function and advantages of color-coated steel plate

Time:2025-01-08

-

What thickness and width of stainless steel do you require?

Time:2025-01-08